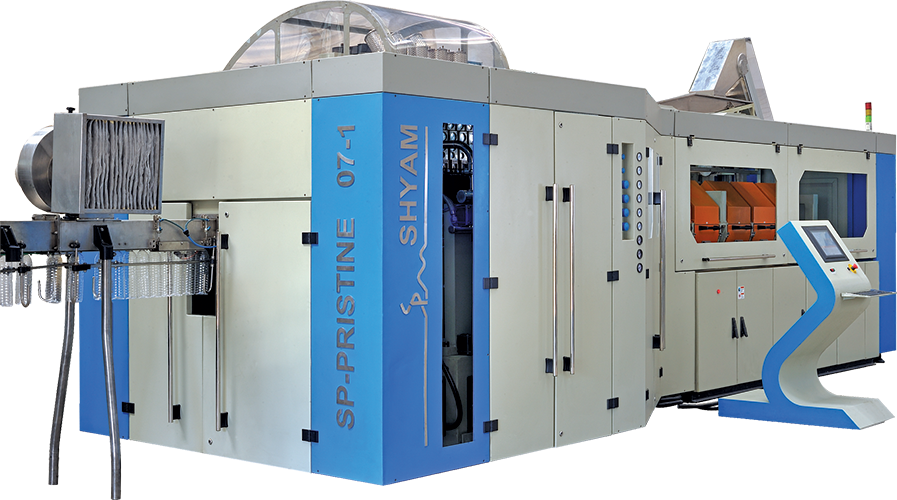

Product Overview

All-Electric Pet Stretch Blow moulding machines, designed to match production rates ranging from 7000 to 12000 bottles per hour. The Fully Automatic Blow Moulding Machine has Close loop heating control and variable speed ventilators for temperature control facilitates this machine to produce consistent quality bottles at higher speeds. The servo stretching features of Pet Stretch Blow Moulding Machines reduces the cycle time, while precisely controlling the primary as well as the final blowing.

Product Specifications

| Description | Unit | SP-Pristine 04-2 |

SP-Pristine 05-1 / 02-2 |

SP-Pristine 06-0.6/02-2 |

SP-Pristine 08-0.3/02-2 |

|||

|---|---|---|---|---|---|---|---|---|

| Machine Specifications | ||||||||

| Mould Clamp | Servo | Servo | Servo | Servo | ||||

| Stretching Type | Servo | Servo | Servo | Servo | ||||

| No. of Cavity | No | 4 | 5 | 2 | 6 | 2 | 8 | 3 |

| Production Per Hour | BPH* | 6000 | 7500 | 3000 | 9000 | 3000 | 12000 | 4500 |

| Nominal Bottle Volume | ml | 2000 | 1000 | 2000 | 600 | 2000 | 300 | 1000 |

| Max Bottle Dia | mm | 105 | 89 | 105 | 76 | 105 | 60 | 89 |

| Max Bottle Height | mm | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| Max Neck Dia | mm | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Air Requirement | ||||||||

| H.P. Air @ 32 bar | CFM | 177 (1000 ml @ 32 Bar) |

217 (1000 ml @ 32 Bar) |

164 (2000 ml @ 32 Bar) |

160 (500 ml @ 32 Bar) |

164 (2000 ml @ 32 Bar) |

152 (300 ml @ 32 Bar) |

137 (200 ml @ 32 Bar) |

| L.P. Air @ 8 bar (without Air Recovery) |

CFM | 28 | 31 | 24 | 33 | 24 | 37 | 26 |

| L.P. Air (after Air Recovery) |

CFM | Nil | Nil | Nil | Nil | Nil | Nil | Nil |

| Electrical Requirement | ||||||||

| Connected Load Without Utility | kW | 88 | 82 | 76 | 90 | |||

| Heating Load | kW | 54 | 48 | 42 | 56 | |||

| Machine Dimensions | ||||||||

| Length | mm | 8600 | 8600 | 8600 | 8600 | |||

| Width | mm | 2850 | 2850 | 2850 | 2850 | |||

| Height | mm | 3350 | 3350 | 3350 | 3350 | |||

| Description | Unit | SP-Pristine 06-2 |

SP-Pristine 07-1 / 03-2 |

SP-Pristine 08-0.6 / 03-2 |

||

|---|---|---|---|---|---|---|

| Machine Specifications | ||||||

| Mould Clamp | Servo | Servo | Servo | |||

| Stretching Type | Servo | Servo | Servo | |||

| No. of Cavity | No | 6 | 7 | 3 | 8 | 3 |

| Production Per Hour | BPH* | 9000 | 10500 | 4500 | 12000 | 4500 |

| Nominal Bottle Volume | ml | 2000 | 1000 | 2000 | 600 | 2000 |

| Max Bottle Dia | mm | 105 | 85 | 105 | 76 | 105 |

| Max Bottle Height | mm | 350 | 350 | 350 | 350 | 350 |

| Max Neck Dia | mm | 30 | 30 | 30 | 30 | 30 |

| Air Requirement | ||||||

| H.P. Air @ 32 bar | CFM | 258 (1000 ml @ 32 Bar) |

299 (1000 ml @ 32 Bar) |

239 (2000 ml @ 32 Bar) |

209 (500 ml @ 32 Bar) |

239 (2000 ml @ 32 Bar) |

| L.P. Air @ 8 bar (without Air Recovery) |

CFM | 33 | 35 | 26 | 37 | 26 |

| L.R Air (after Air Recovery) |

CFM | Nil | Nil | Nil | Nil | Nil |

| Electrical Requirement | ||||||

| Connected Load Without Utility | kW | 106 | 98 | 90 | ||

| Heating Load | kW | 72 | 64 | 56 | ||

| Machine Dimensions | ||||||

| Length | mm | 9500 | 9500 | 9500 | ||

| Width | mm | 2850 | 2850 | 2850 | ||

| Height | mm | 3350 | 3350 | 3350 | ||

| Description | Unit | SP-Pristine 08-1 / 04-2 |

SP-Pristine 10-0.6 / 05-1 |

SP-Pristine 12-0.3 / 6-1 |

||||

|---|---|---|---|---|---|---|---|---|

| Machine Specifications | ||||||||

| Mould Clamp | Servo | Servo | Servo | |||||

| Stretching Type | Servo | Servo | Servo | |||||

| No. of Cavity | No | 8 | 4 | 10 | 5 | 12 | 6 | |

| Production Per Hour | BPH* | 12000 | 6000 | 15000 | 7500 | 18000 | 9000 | |

| Nominal Bottle Volume | ml | 1000 | 2000 | 600 | 1000 | 300 | 1000 | |

| Max Bottle Dia | mm | 90 | 105 | 76 | 90 | 60 | 85 | |

| Max Bottle Height | mm | 350 | 350 | 350 | 350 | 350 | 350 | |

| Max Neck Dia | mm | 30 | 30 | 30 | 30 | 30 | 30 | |

| Air Requirement | ||||||||

| H.P. Air @ 32 bar | CFM | 339 (1000 ml @ 32 Bar) |

314 (2000 ml @ 32 Bar) |

258 (500 ml @ 32 Bar) |

217 (1000 ml @ 32 Bar) |

220 (300 ml @ 32 Bar) |

248 (1000 ml @ 32 Bar) |

|

| L.P. Air @ 8 bar (without Air Recovery) |

CFM | 39 | 30 | 43 | 32 | 48 | 35 | |

| L.P. Air (after Air Recovery) |

CFM | Nil | Nil | Nil | Nil | Nil | Nil | |

| Electrical Requirement | ||||||||

| Connected Load Without Utility | kW | 92 | 92 | 92 | ||||

| Heating Load | kW | 56 | 56 | 56 | ||||

| Machine Dimensions | ||||||||

| Length | mm | 10100 | 10100 | 10100 | ||||

| Width | mm | 2850 | 2850 | 2850 | ||||

| Height | mm | 3350 | 3350 | 3350 | ||||

| Description | Unit | SP-Pristine 10-1 / 05-2 |

SP-Pristine 12-0.6 / 05-2 |

SP-Pristine 16-0.25 / 08-0.6 |

|||

|---|---|---|---|---|---|---|---|

| Machine Specifications | |||||||

| Mould Clamp | Servo | Servo | Servo | ||||

| Stretching Type | Servo | Servo | Servo | ||||

| No. of Cavity | No | 10 | 5 | 12 | 5 | 16 | 8 |

| Production Per Hour | BPH* | 15000 | 7500 | 18000 | 7500 | 24000 | 12000 |

| Nominal Bottle Volume | ml | 1000 | 2000 | 600 | 2000 | 250 | 600 |

| Max Bottle Dia | mm | 90 | 105 | 76 | 105 | 56 | 76 |

| Max Bottle Height | mm | 350 | 350 | 350 | 350 | 350 | 350 |

| Max Neck Dia | mm | 30 | 30 | 30 | 30 | 30 | 30 |

| Air Requirement | |||||||

| H.P. Air @ 32 bar | CFM | 420 (1000 ml @ 32 Bar) |

388 (2000 ml @ 32 Bar) |

306 (500 ml @ 32 Bar) |

388 (2000 ml @ 32 Bar) |

260 (250 ml @ 32 Bar) |

209 (500 ml @ 32 Bar) |

| L.P. Air @ 8 bar (without Air Recovery) |

CFM | 45 | 33 | 49 | 33 | 59 | 40 |

| L.P. Air (after Air Recovery) |

CFM | Nil | Nil | Nil | Nil | Nil | Nil |

| Electrical Requirement | |||||||

| Connected Load Without Utility | kW | 116 | 106 | 108 | |||

| Heating Load | kW | 80 | 70 | 72 | |||

| Machine Dimensions | |||||||

| Length | mm | 11100 | 11100 | 11100 | |||

| Width | mm | 3150 | 3150 | 3150 | |||

| Height | mm | 3350 | 3350 | 3350 | |||

* Specifications subject to change. *Output varies with bottle design and preform weight & design.

Product Features

Preform Handling

- Loading on Oven Mandrels using Turret Wheel System.

Heat Conditioning

- Close Loop Heating Control (Auto Preform Temperature Control).

- Variable speed ventilators for accurate Chamber Temperature Control.

Stretching

- Servo Stretching in Dual mode in synchronization with Mould Clamp, to reduce cycle time.

- Precise control of Preblow (Primary Blow) and Blowing (Final Blow).

- Reduced Frictional and Inertia loss.

Mould Clamp

- Electrical Mould Clamp using servo system.

- Mould Compensation for faster and positive locking without vibration.

- Synchronized with Stretching functions.

Energy Saving

- No Low Pressure Air required. Blowing air is recovered and re-collected to be used for machine operations and remaining air to be fed back to booster compressor.

Product Application

Upto 8 Cavity - 6000 to 12000 Bottles / Hour