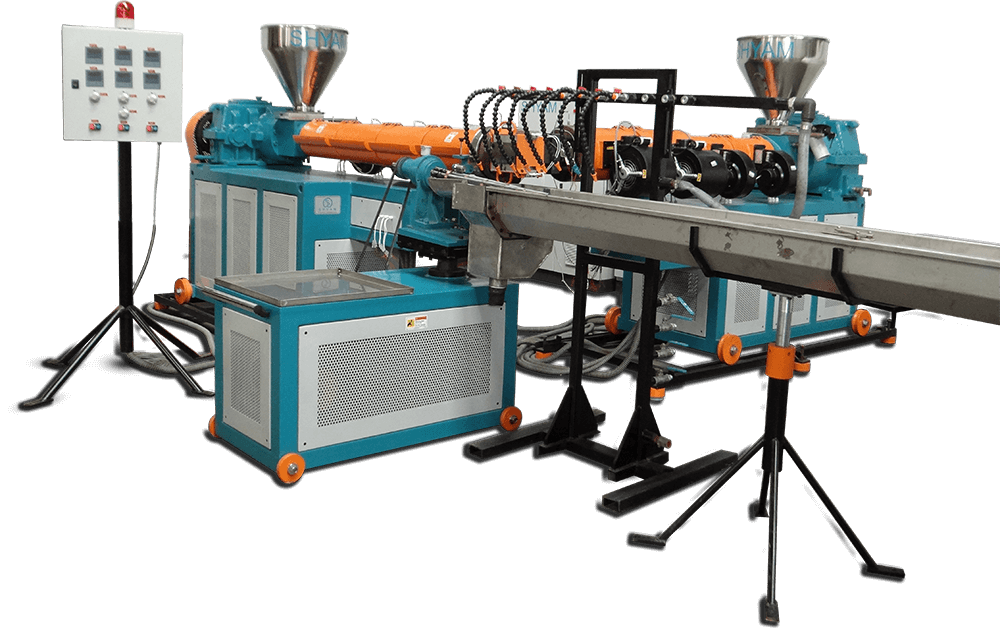

Product Overview

SHYAM's experience in suction hose plant dates back to 1976. Our technical know-how of the suction hose system and knowledge of processing is the reason for excellent quality of final products with unmatched energy efficiency. Our aim of giving competitive edge to customers has been an impetus in achieving reduced energy consumption from 0.32 units/kg to 0.24 units/kg. We have successfully responded to the needs of our customers in developing new and customized applications for the suction hoses.

Product Specifications

| PVC Suction Hose Plant | EX 4550 | EX 5065 | EX 6570 | EX 7075 |

|---|---|---|---|---|

| Extruder - Rigid | ||||

| Single Screw Dia. | 45mm | 50mm | 65mm | 70mm |

| L:D Ratio | 21:1 | 25:1 | 25:1 | 25:1 |

| Motor | 7.50 kW | 11.25 kW | 15 kW | 15 kW |

| Extruder - Soft | ||||

| Single Screw Dia. | 50mm | 65mm | 70mm | 75mm |

| L:D Ratio | 21:1 | 25:1 | 25:1 | 25:1 |

| Motor | 5.65 kW | 11.25 kW | 15 kW | 15 kW |

| Former | ||||

| Motor | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Min. Pipe ID | 3/4" | 3/4" | 2" | 3" |

| Max. Pipe ID | 11/2" | 8" | 8" | 8" |

| Cooling Truff Material | SS | SS | SS | SS |

| Length | 34 mtrs | 34 mtrs | 34 mtrs | 34 mtrs |

| Heating & Cooling | ||||

| Barrel & Heating Zones | 8 nos | 8 nos | 8 nos | 8 nos |

| Blower for cooling | 8 nos | 8 nos | 8 nos | 8 nos |

| Die Heating Zones | 6 nos | 6 nos | 6 nos | 6 nos |

| Heating Load | 19 kW | 21 kW | 26 kW | 30 kW |

| Moter & Blowers | 17 kW | 26 kW | 34 kW | 41 kW |

| Production kg / Hr. | 30 | 60 | 90 | 110 |

| Range | 3/4" to 2" | 3/4" to 8" | 2" to 8" | 3" to 8" |

| Connected Load (Without Utilities) |

36 kW | 47 kW | 60 kW | 71 kW |

* Specifications subject to change.

Product Application

PVC Suction Hose is widely used in Agriculture, Fluid & Chemical Transfer, Food & Syrup Handling, General Water Suction & Discharge, Hopper Feeder Lines for Resin, Irrigation Lines, mining Pumps, Pneumatic Conveyance of Granular Materials, Vacuum Lines, etc.